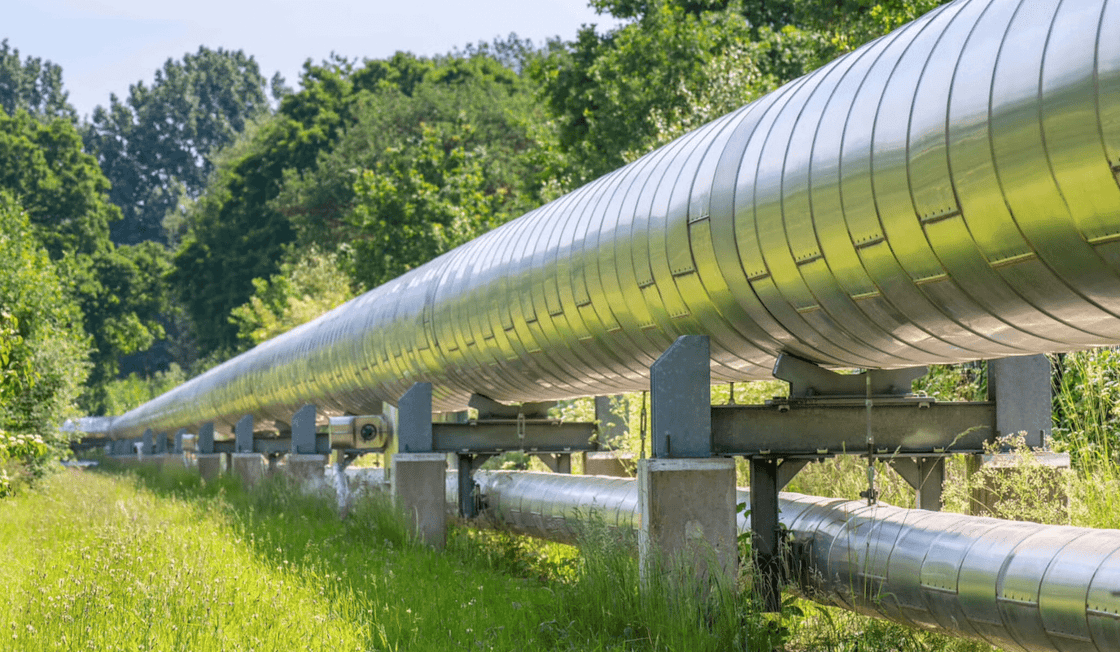

The graph shows how the impedance curves change dynamically during a charging cycle. The curves provide information on the physical and chemical processes taking place inside the battery cell.

As battery systems become the backbone of electric mobility, renewable energy storage, and grid resilience, real-time monitoring and intelligent management are emerging as critical enablers of performance, safety, and longevity. A new innovation from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM introduces a transformative approach to battery diagnostics—dynamic impedance spectroscopy during live operation.

Conventional battery diagnostic methods require systems to pause operation to measure internal parameters, often taking up to 20 minutes to generate meaningful insights. This downtime limits responsiveness and reduces the ability to detect fast-developing risks such as thermal runaway or cell degradation.

Fraunhofer IFAM’s dynamic impedance spectroscopy overcomes this limitation by analyzing a battery’s internal state in real time while it is charging or discharging. The system superimposes a multi-frequency test signal onto the battery’s operating current, enabling continuous, high-resolution measurement—up to 1 million samples per second—of electrochemical and thermal processes occurring inside the cell.

By tracking real-time changes in internal impedance—an essential indicator of State of Charge (SoC) and State of Health (SoH)—battery management systems can optimize charging and discharging behavior. This allows operators to reduce wear, slow degradation, and extend usable battery life, improving total lifecycle economics for EV fleets, grid storage, and industrial applications.

Safety is a critical concern for large-scale battery deployments. Fraunhofer’s real-time method enables rapid detection of localized overheating, internal stress, or early-stage failure events—often before surface temperature sensors can react. This allows systems to throttle or isolate affected cells immediately, reducing the risk of fire, damage, or catastrophic failure.

This capability makes batteries more suitable for safety-critical applications, including aviation, emergency-response vehicles, and mission-critical grid storage, where reliability and fast fault response are essential.

The Fraunhofer IFAM technology delivers several notable advancements:

- Live operational measurement during active charge/discharge cycles

- High-frequency signal resolution up to 1 MHz for deep internal profiling

- Efficient data-reduction algorithms enabling rapid real-time processing

- Predictive analytics to inform smarter charging protocols

- Compatibility across battery chemistries, including lithium-ion, solid-state, and next-generation systems

Dynamic impedance curves generated during charging cycles reveal evolving internal electrochemical behavior, providing unprecedented insight into battery health and performance trends.

The implications of this technology span multiple industries:

- Electric Vehicles (EVs): Safer, longer-lasting battery packs with optimized performance

- Renewable Energy Storage: Intelligent control for solar and wind battery systems

- Grid & Microgrids: Reliable, long-life energy storage with improved operational stability

- Aviation & Marine: Enabling high-reliability electric propulsion and storage

- Industrial Backup Power: Enhanced confidence in mission-critical power systems

By unlocking real-time visibility into battery health and internal dynamics, Fraunhofer IFAM’s innovation marks a significant leap forward in battery intelligence. The technology has the potential to reshape how batteries are managed—making them safer, more durable, and more viable for high-demand and safety-sensitive applications.

Subscribe to get the latest posts sent to your email.