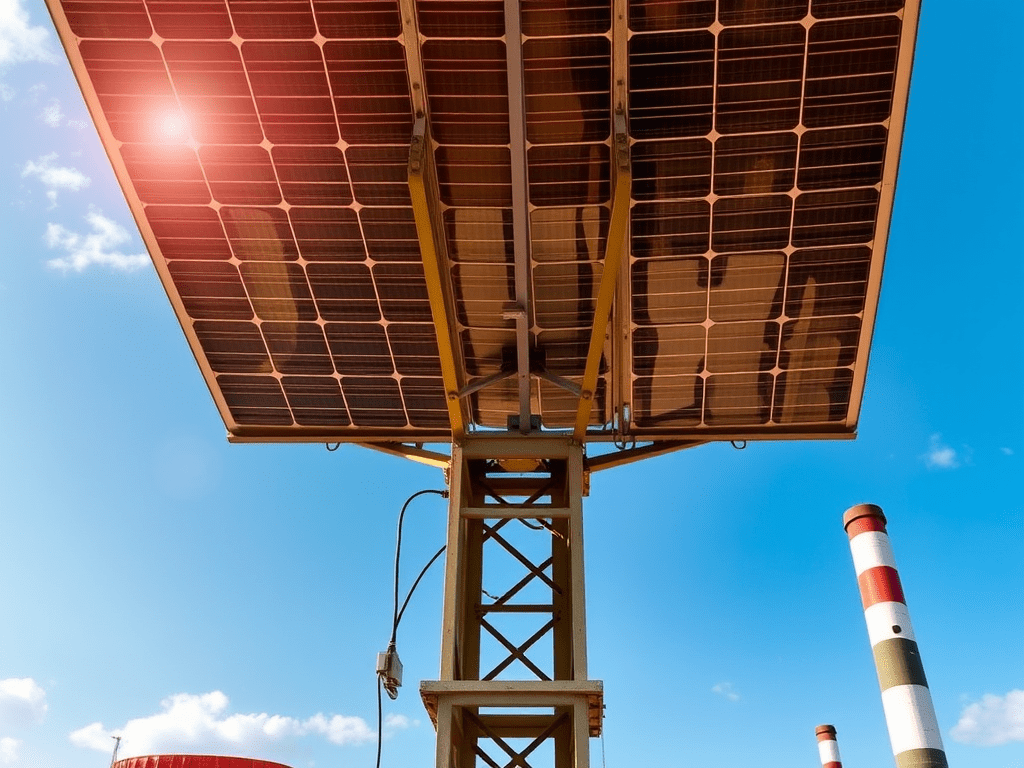

A study by the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) has revealed a growing discrepancy between the power output specifications of photovoltaic (PV) module manufacturers and the actual performance measured in laboratory tests. The findings, based on an extensive evaluation of over 70,000 PV module power measurements conducted since 2012 at the institute’s CalLab PV Modules, suggest that module performance has been consistently overstated in recent years.

Until 2016, Fraunhofer ISE’s laboratory measurements often showed PV modules delivering more power than their manufacturers claimed. However, a negative trend has emerged since 2017, with the discrepancy widening significantly between 2020 and 2023, leading to an average power reduction of about 1.3 percent compared to manufacturer specifications. Preliminary 2024 data indicates a slight reversal in this trend, but power deviations remain negative at 1.2 percent on average.

The research team, led by Daniel Phillip, head of the Department of Module Characterization and Reliability at Fraunhofer ISE, analyzed 1,034 performance measurements of monocrystalline silicon PV modules under standardized conditions. Their findings were presented at the 40th PV Symposium in Bad Staffelstein this week. Phillip noted that while deviations before 2016 were within an acceptable range, the growing negative discrepancies in recent years highlight a potential issue with overly optimistic power ratings by manufacturers.

According to Phillip, if the Fraunhofer ISE data is representative of the German PV market, the observed 1.2 percent underperformance in 2024 translates to an overall power shortfall of approximately 195 megawatts, equivalent to the output of one of Germany’s largest solar parks.

Prof. Andreas Bett, Institute Director at Fraunhofer ISE, emphasized the importance of independent quality control for PV modules, particularly as over 90 percent of PV components in the German and European markets are imported. The study filtered data rigorously to ensure accuracy, excluding inconsistent or statistically distorting samples and only considering modules from top 10 manufacturers each year.

Fraunhofer ISE has maintained a stable calibration standard over the years, verified by regular interlaboratory comparisons. The institute’s findings underscore the need for continuous monitoring and independent verification to maintain transparency and trust in the solar industry.