Major Solar-Plus-Storage Project Announced in Middle East. A solar-plus-storage project that could provide gigawatts of generation capacity was unveiled in January during Abu Dhabi Sustainability Week (ADSW). Dr. Sultan Al Jaber, minister of industry and advanced technology for the United Arab Emirates (UAE) and chairman of state-owned renewables company Masdar, announced plans for the renewable energy power station plant at the opening ceremony of ADSW. The project would include 5.2 GW of solar photovoltaic generation with 19 GWh of battery energy storage capacity, which Al Jaber said would enable the plant to provide as much as 1 GW of baseload power on a continuous basis. The project will be based in Abu Dhabi, though the specific location was not announced. The installation will be delivered by Masdar and the state electricity and water procurement and supply entity Emirates Water & Electricity Co. with partners.

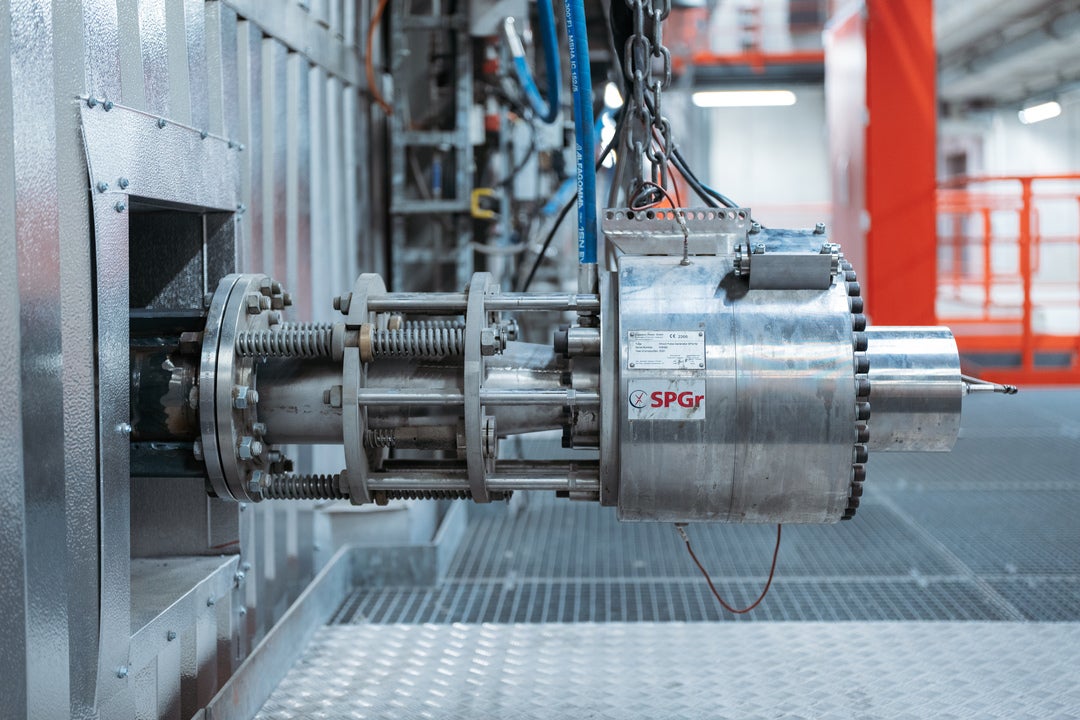

Wärtsilä Engines Will Power Kazakhstan Power Plant. Technology group Wärtsilä said it will supply the engineered equipment for a new 120-MW power plant under construction in Kazakhstan. The order announced in January was placed by Kazakhstan Caspian Offshore Industries (KCOI) and booked by Wärtsilä in late 2024. The order includes six Wärtsilä 46TS-SG gas-fueled large bore engines, as well as mechanical and electrical auxiliary equipment. KCOI is the main contractor for the development of a major hybrid power project in the Mangystau region, which in addition to the engine power plant will include a 77-MW wind power plant and a 50-MW solar power plant. The project once commissioned will supply electricity to oil and gas exploration facilities in the region. Mirko Borghesi, CEO of KCOI, said it will be the first hybrid project of its type to be implemented in Kazakhstan. Delivery of the Wärtsilä equipment is scheduled by the end of this year, and the project is expected to be fully operational by the middle of next year.

BESS Project Under Construction in Germany. France-headquartered Neoen, an independent power producer (IPP), in January said the company has started construction work on a 45-MW/90-MWh battery energy storage system (BESS) project in Saxony-Anhalt, Germany. The installation is scheduled to enter commercial operation next year. The Arneburg Battery project is the first BESS installation for Neoen in Germany. The IPP will own 100% of the Arneburg Battery, and will also operate the project. Arneburg will participate in both intraday power trading and balancing services. Neoen said it has a “robust” pipeline of projects in Germany, with more than 1 GW of generation capacity at various stages of development. The company, which is set to be acquired by infrastructure investor Brookfield, has a global generation portfolio in operation or under construction of about 2.3 GW, with 5.3 GWh of energy storage. Neoen said it also is building the 93.9-MW Isbillen Power Reserve BESS project in Sweden, and the 56.4-MW BESS Yllikkälä Power Reserve Two project in Finland.

Major Pumped Storage Project Comes Online in China. Chinese officials in January said the Fengning Pumped Storage Power Station began commercial operation on Dec. 31, 2024. Officials said it is the largest pumped storage facility in the world and includes 12 reversible pump-turbine units, each with a capacity of 300 MW, including two variable-speed units, bringing the total installed capacity to 3.6 GW. It is designed to generate 6.61 TWh annually while consuming 8.71 TWh of electricity for pumping. It is connected to the North China power grid via four 500-kV transmission lines. The facility is located in Fengning County, Hebei Province, near Beijing and Tianjin, and in proximity to the 10-GW wind and solar power complex in Zhangjiakou. The storage project was developed by State Grid Xinyuan Group Co., a subsidiary of the State Grid Corp. of China. Officials said construction of the project took more than 11 years after starting in May 2013, and represents an investment of about $2.6 billion.

Valmet Modernizing Heating Plant in Czech Republic. Valmet in late January said the company will support the modernization of ŠKO-ENERGO’s heating plant in Mladá Boleslav, Czech Republic. The project includes converting two existing circulating fluidized bed (CFB) boilers from coal to biomass and delivering a new bubbling fluidized bed (BFB) boiler. The order also includes a flue gas cleaning system for the new boiler and modifications to the flue gas cleaning systems of the upgraded boilers. Valmet said that the new BFB boiler will compensate for the reduced capacity from the converted CFB boilers. The new boiler will work alongside the retrofitted equipment. Officials said the CFB boilers will burn a biomass mix of wood chips and agro-biomass pellets. The Mladá Boleslav plant supplies power to Škoda Auto’s manufacturing facilities, and provides heat for the town. ŠKO-ENERGO called the project a significant milestone in the company’s efforts toward decarbonization. The project is expected to be completed by year-end 2027, with work done consecutively across a two-year time frame to ensure that the heat and power supply to the car manufacturing facility can continue without interruption. The new Valmet BFB will produce steam at a rate of 80 tons per hour using wood chips as fuel. The rebuilt CFBs, which delivered 140 tons of steam per hour when burning coal, will have a new capacity of 100 tons of steam per hour burning wood chips and biomass pellets.

—Darrell Proctor is a senior editor for POWER.